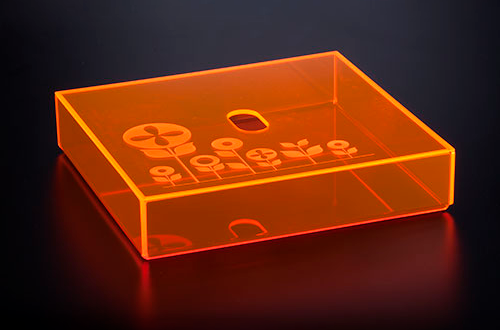

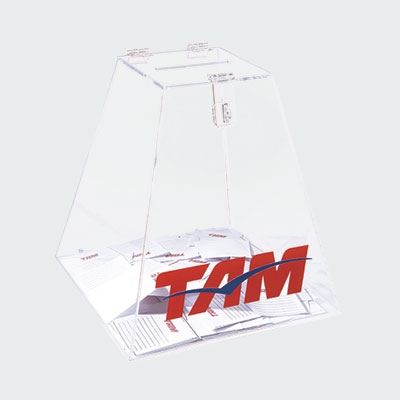

Extruded Acrylic Sheets

Extruded Acrylic Sheets have a high degree of transparency and quality. Created from the compression of acrylic grains through a conventional extrusion screw, they are the most common option for the production of acrylic sheets and, therefore, the lowest cost alternative among all options.