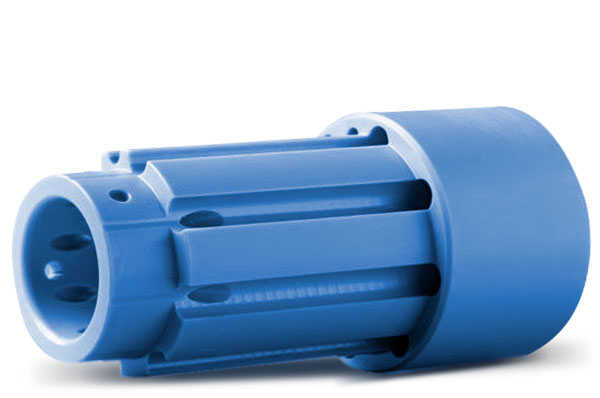

PEEK

PEEK engineering plastic is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance, capable of maintaining its properties at high temperatures. The processing conditions used to shape PEEK may influence its crystallinity and improve mechanical properties. Being a high performance plastic, it is applicable to almost every industry branch.