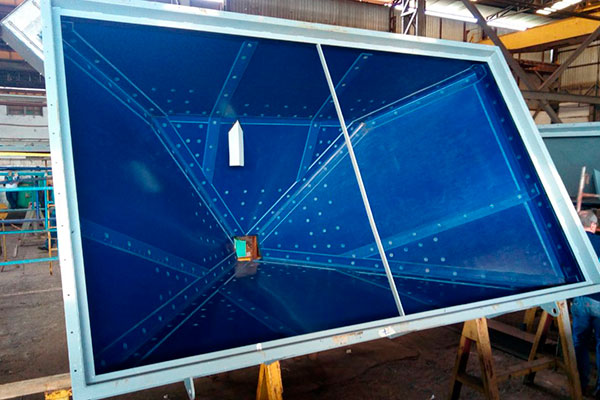

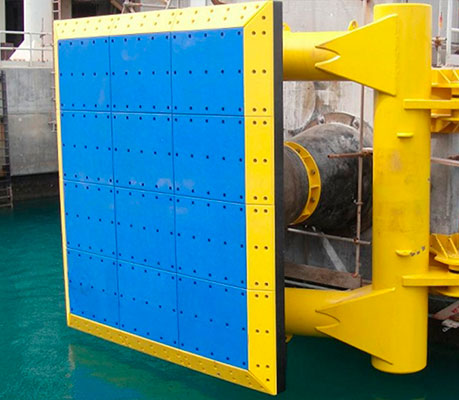

UHMW Plastic

UHMW plastic is a high molecular weight polyethylene, which gives it technical characteristics that make it superior to any other plastic in this category. Obtained through a Thermo-compression or RAM Extrusion process, UHMW has high resistance to impact and abrasion wear, being more indicated where moving parts cause friction.